TRION Kitchen Exhaust Purification System

TRION Kitchen Exhaust Purification System and Solutions

TRION is focusing on the air purification field for more than 70 years since 1947, with the advanced technology and rich experience. TRION is dedicated to provide customers worldwide with high-quality, technology-leading kitchen purification products and system solutions.

Kitchen Purification System Schematic Diagram

Kitchen purification systems involves two parts: oil fume purification, and oil fume odor treatment.

Product Series

Kitchen purification includes grease, oil smoke purification, and odor treatment. TRION provides efficient purification equipment for these two parts to meet user needs, as well as fire protection and environmental protection requirements.

TRION Kitchen Oil Purification Series

TRION Odor Purifying Series

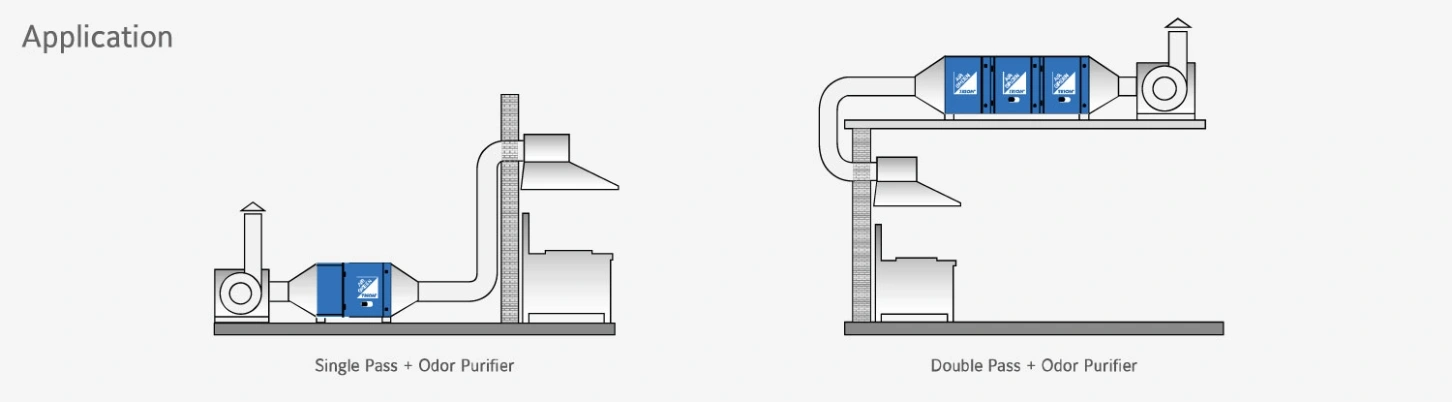

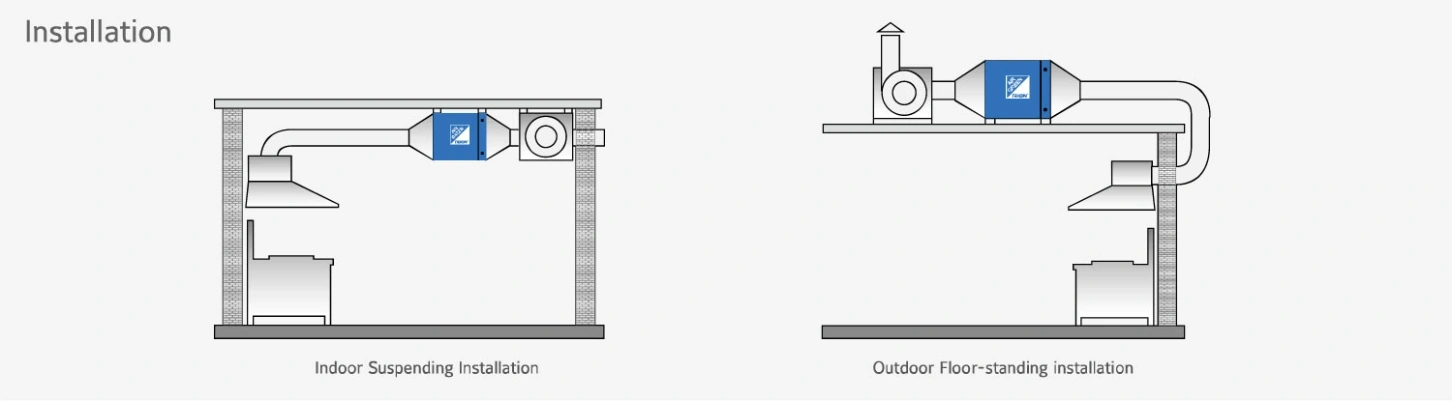

Purification System Application and Installation

TRION can flexibly provide a variety of system solutions based on customer's kitchen oil fume volume and emission requirements, and the required installation location. That will completely solve the cooking fume problem, meet emission standards, and create a clean and healthy living environment.

TRION Kitchen Exhaust Air Cleaner

The principle of electrostatic purification technology

- The dirty air will firstly go through the primary filter, large particles of pollutants in the air are intercepted, and the smaller particles which escaped through the primary filter will enter the ionization zone;

- In the ionization zone, particles as small as 0.01 μm are effectively ionized and carry a positive charge to continue to the dust collection area;

- The dust collection area is composed of many parallel plates. These charged particles are then attracted to and adhere to this series of parallel plates, which form the negative elements of an electrostatic field;

- The clean air enters the activated carbon filter (optional), and the odor molecules will be absorbed by the activated carbon filter; the clean and fresh air will sent back to the room or discharged into the atmosphere.

EFB and AHU combine to purify air

The EFB works in tandem with the air handling unit (AHU) to purify returning air into fresh, clean air. This process provides a variety of purification solutions, depending on specific requirements. You are then guaranteed cost-effective and highly efficient air purification.

Selection Process

Calculate and confirm selection results - Single Calculation

1. Select AHU to be calculated (not check box)

2. Select EFB configuration

3. Click “Calculate”

4. Select one result at “Selection Result” area and click “OK”to confirm