The Dynamic V8 Air Cleaning Systems

A New Level of Performance and Savings from

a New Category of Air Cleaner

The Dynamic V8 is the new standard in air cleaning-outperforming anything on the market in contaminant control, maintenance and cost of ownership.

Designed to meet the rigorous requirements of Green buildings, data centers, hospitals, pharmaceutical and clean manufacturing, the Dynamic V8 Air Cleaning System couples maximum effectiveness with unparalleled energy and operational savings.

The Dynamic V8 utilizes both the principles of existing Dynamic products as well as several important technological advances to create a system that is a quantum leap over the current state of the art.

The New Standard in Air Cleaning

The Dynamic V8 provides MERV 13-16 performance without ionizing or Ozone generation– plus VOC reduction and superior capture of dangerous ultra-fine particles. It is constructed to eliminate bypass, a critical issue for maximum performance. Further, because of the various mechanisms of the Dynamic V8, the MERV results understate the real-world effectiveness, as shown below. A typical MERV 14 passive filter will leave behind four times as many 0.3 micron particles. In actual installations, levels of ultra-fine particles and black carbon were over 90% lower than outdoor levels.

V8 Results

In a highly urban environment, the Dynamic V8 provided indoor air with levels of ultra fine particles and black carbon from vehicle exhaust that were over 90% betterthan the levels in the outdoor air.

V8 Longevity

As of September 2010, the first Dynamic V8 installations have been in service for over 2 1⁄2 years. No pre-filters are used. Pressure drop has increased only .2” w.g. The air cleaners will have many more months of operation before the media needs to be replaced.

Lowest Life-Cycle Cost / Longest Life

- Energy, maintenance and disposal account for over 90% of the cost of filtration.

- The Dynamic V8 slashes all three to deliver operating costs that are 1/3 that of alternatives.

- Typical paybacks are less than three years.

Maximum Loading

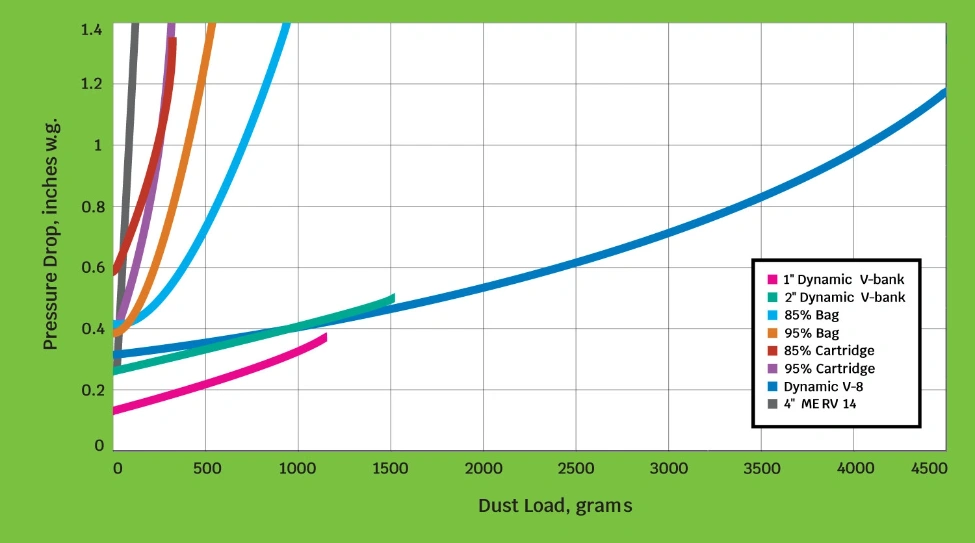

The Dynamic V8 holds up to ten times the dust of standard cartridge and bag filters and up to 100 times the dust of shallow-bed passive filters. Loading is critical to the ongoing costs of filtration, but is often overlooked or not reported. Unlike passive filters (which load primarily on the face of the media), the Dynamic V8 loads throughout the full 1” depth of each of the eight media pads and 360° around each fiber. This three-dimensional loading accounts for the V8’s dramatic ability to collect contaminants. And the active-field technology tightly holds what has been collected so it is not shed back into the airstream.

Longest Maintenance Cycles

Dramatic loading means a typical maintenance cycle should be over three years. That means no quarterly pre-filter changeouts and nine-month final filter replacements. That frees up a lot of time for maintenance personnel to concentrate on other things. Less media changes also means less material use, less disposal costs and a smaller environmental footprint for the building.

Maximum Energy Savings

Superior loading also flattens the pressure drop curve to save over 1” of static. This means big energy savings and the potential for smaller fan selection. Energy costs are a major concern for facility managers and are, at current rates, typically 80-85% of the cost of filtration, far outweighing initial filter cost. A MERV 14 cartridge filter array with pre-filters will consume three times more energy than a Dynamic V8.

Green Design and LEED

- The Dynamic V8 is completely consistent with the goals of LEED and Green Design: it does more with less: more IAQ, less energy, less time, less waste.

- It is the choice for LEED projects and is installed throughout the LEED Platinum renovation of ASHRAE Headquarters and in numerous projects around the world.

- Whether you are seeking LEED certification or simply designing with Green principles in mind, the Dynamic V8 provides the highest level of performance with the minimum environmental footprint.

V8 Energy & Carbon

On a 20,000 cfm air handler, the V8 can save up to 30,000 kWh and 40,000 pounds of CO2 per year versus passive alternatives.

V8 LEED Projects

Dynamic V8 Air Cleaners are installed throughout the LEED platinum renovation of ASHRAE headquarters and in numerous LEED projects throughout the world.

The Dynamic V8 outperforms anything on the market

Above is a bank of V8’s in a 125,000 cfm custom air handler in a high-risk office application. These units are permanently mounted with front access.

This is a slide out Dynamic V8 module in a filter box for a fan coil unit. These give a MERV 13 option for smaller equipment in LEED projects. This module was part of those that were installed throughout the LEED EB renovation of ASHRAE headquarters.

Configurations and Applications

The Dynamic V8 Air Cleaner can be configured and fine-tuned for a wide range of applications and equipment types. The Dynamic V8 modules can be factory or field installed in the filter section of air handlers configured for high-efficiency passive filtration. Because of its low pressure drop and flat loading curve, the Dynamic V8 can also be used with smaller equipment such as packaged rooftops, fan coils, heat pumps, and VRF units. Here, the Dynamic V8 modules are installed and accessed in external filter sections.

Dynamic Technology

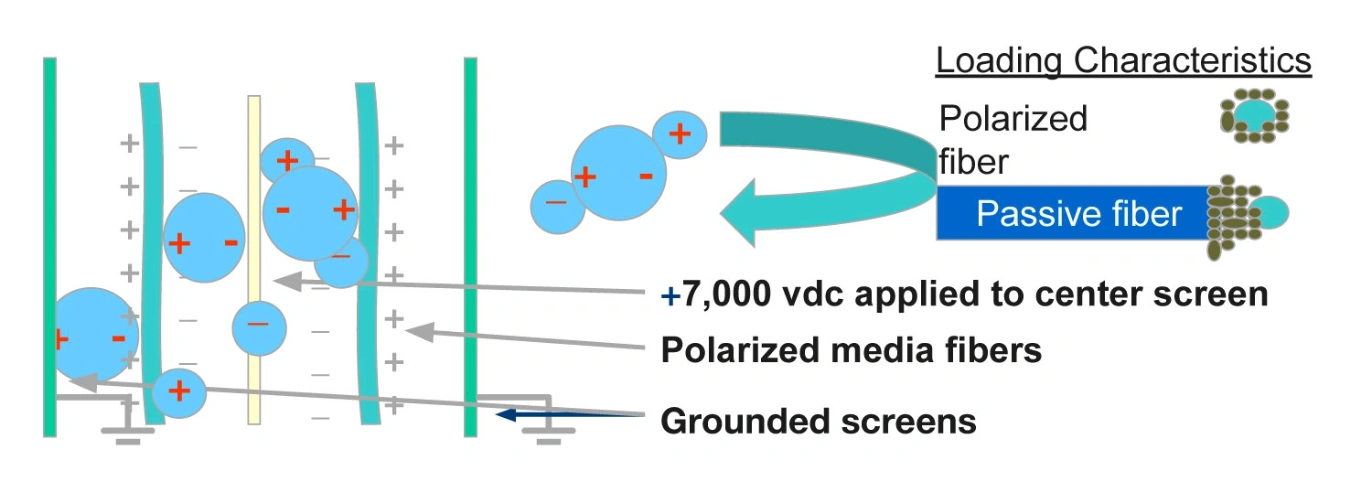

One inch panel however technology in all Dynamics is the same.

Dynamic Technology

Passive Mechanisms:

Because there is a media, there is a passive collection.

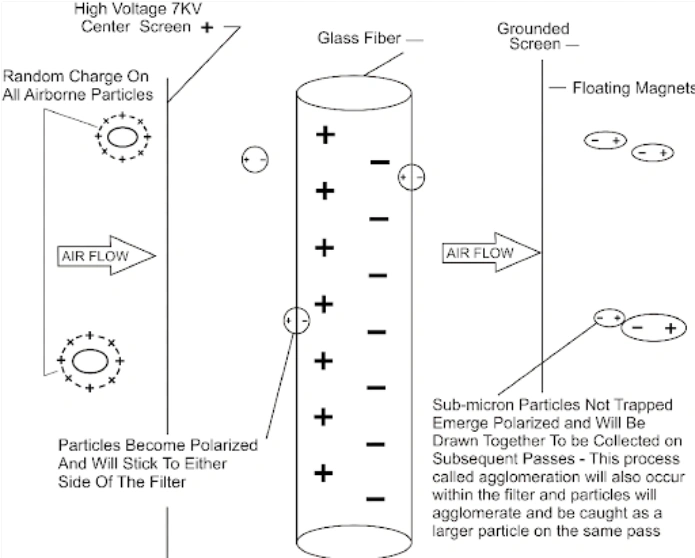

Polarization And Electrostatic Attraction:

- Polarized fibers collect polarized and charged particles.

- Charged center screen collects polarized and charged particles.

Agglomeration:

- Natural process (Brownian Motion) greatly accelerated by the field inside the air cleaner. Polarized particles attract each other and charged particles to form clusters that are more easily captured.